Business Central Warehouse Management

Content menu

Inventory management

In short, the purpose of inventory management is to reduce the company's storage costs without compromising service levels resulting in dissatisfied customers.

Poor inventory management can be a really expensive problem, which has a negative and direct influence on the company's cash flow and can therefore ultimately have catastrophic financial consequences. Inaccurate inventory can lead to product shortages, delays, and inventory levels that are either too high or too low, resulting in unhappy customers and greatly damaging the business.

For many companies, there is both increased efficiency and cost savings to be gained by optimizing inventory management.

Purpose of inventory management:

- Received items are handled correctly

- the amount of redundant parts and products is minimized

- The demand for your products is met

- Ability to track products

- Live up to demand and demand

- Collectible by item data

Inventory management in Business Central

Connect your inventory, its internal activities, purchase orders and invoices through a flexible and scalable solution. The warehouse management functionality in Business Central not only provides insight into each shipment or process, but optimizes storage processes to maximize utilization of storage space. Real-time alerts to Business Central provide accurate and immediate feedback on status queries.

|

Manage your inventory

Business Central offers functionality for inventory tracking, order fulfillment, real-time stock visibility, and integration with supply chain processes. This leads to improved accuracy, reduced errors, increased efficiency, and better decision-making in managing warehouse activities.

|

Keep your inventory up to date

Create financial account records, record increases and decreases in the number of items, monitor your inventory status across locations.

Effectively manage your internal storage activities

With BusinessCentral, you gain control over all common work processes in your warehouse, such as removing and moving items.

Improve order execution

Business Central allows you to follow each order and therefore give your customers an accurate order status.

Create purchase orders

A purchase order represents an agreement with a supplier to purchase goods or services. Business Central makes it easy and quick to create a purchase order.

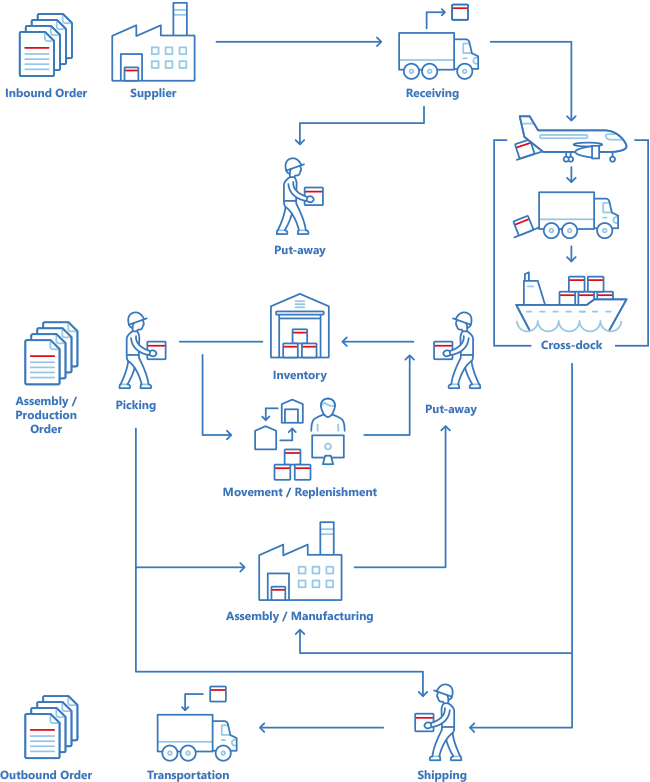

Warehouse flow and logistics overview

In order to support the physical handling of your goods at zone and bin level, all information is tracked for every transaction or movement in the warehouse. In Business Central this is managed in the Warehouse Entry table. Each individual transaction is stored in an inventory journal.

In order to register item movements in your warehouse, Business Central uses warehouse documents and a warehouse journal. Every time an item in the warehouse is received, put away, moved, picked, adjusted or shipped, warehouse entries are registered in Business Central for the purpose of storing the physical information about zone, quantity and location.

You use Bin Content table in Business Central to manage all the different dimensions of the contents of a bin per item, it can be, for example, unit of measure, maximum quantity and minimum quantity. The Bin Content table also contains flow fields of the warehouse instructions, warehouse entries and warehouse journal lines, which means that the availability of an item per bin and a bin for an item quickly can be calculated.

When item postings occur outside the Business Central warehouse module itself, a default adjustment bin per location is used for synchronizing inventory entries with inventory warehouse. When your warehouse employees carry out a physical stock count, any differences between the calculated number of items and the actual number of items counted are recorded in the adjustment bin, and subsequently posted as corrected item ledger entries.

Illustration of a typical warehouse flow

Basic or advanced warehouse logistics

The warehouse functionality in Business Central can be implemented at different levels of complexity, depending on your company's business processes and order volume.

The main difference between basic and advanced warehouse logistics is that the warehouse activities are carried out order by order in basic warehouse and consolidated for multiple orders in advanced inventory management.

Inventory management FAQ

Here you can get answers to any questions you may have regarding Warehouse Management. If you have questions that are not answered below, you are of course very welcome to contact us here.

The term warehouse management covers the internal processes that take place in relation to the management of a warehouse. Inventory management helps you get a clear and structured overview of your inventory and gives you the opportunity to optimize the inventory processes and thus improve your earnings and business. With inventory management, you can, for example, see which items are in stock and which items need to be reordered. You can also see which items are selling as you expected and which are not.

Warehouse management is crucial for ensuring efficient storage, organization, and movement of goods within a warehouse. It helps optimize inventory management, reduce operational costs, improve order accuracy, enhance productivity, and ensure timely delivery to customers.

What is good inventory management?

When aiming for efficient and flexible stock management, it is to limit stock costs without affecting the service level. An inventory management system should be an integrated part of your financial system, so that the sales that are registered automatically count down on your inventory. If you sell products online via a webshop, it is also a good idea to integrate your warehouse with your webshop, so that your customers in the purchasing situation can see whether the product they want to buy is actually in your warehouse.

Why Business Central for inventory management?

The warehouse management functions in Business Central not only give you insight into each individual shipment or storage process, but optimize all the processes in your warehouse so that the greatest possible utilization of your warehouse space is achieved. With immediate real-time reports, you get precise feedback on status inquiries in a flash.